Accelerating Crop Improvement in the Plant Transformation Facility

“The moment I see a transgenic plant, it makes me happy because it could become a product that makes an impact on people one day,” says Dr. Veena Veena, MBA, Director, Plant Transformation Facility.

Veena joined the Danforth Center in 2016, after working at Monsanto. In her previous role in an industry setting, she saw the need in academia for plant transformation expertise. “I was inspired to return to an academic setting to offer my services and experience to make an impact and help feed the world more sustainably.”

Today, Veena is the Director of the Danforth Center’s Plant Transformation Facility. The Plant Transformation facility collaborates with Danforth Center scientists, 39 North companies, and international partners to produce genetically engineered plants that make vital improvements in agriculture. By collaborating with the core facility, plant scientists can improve key crop characteristics, like drought tolerance and disease resistance, at an accelerated rate.

Plant Transformation Facility is a Vital Resource in 39 North

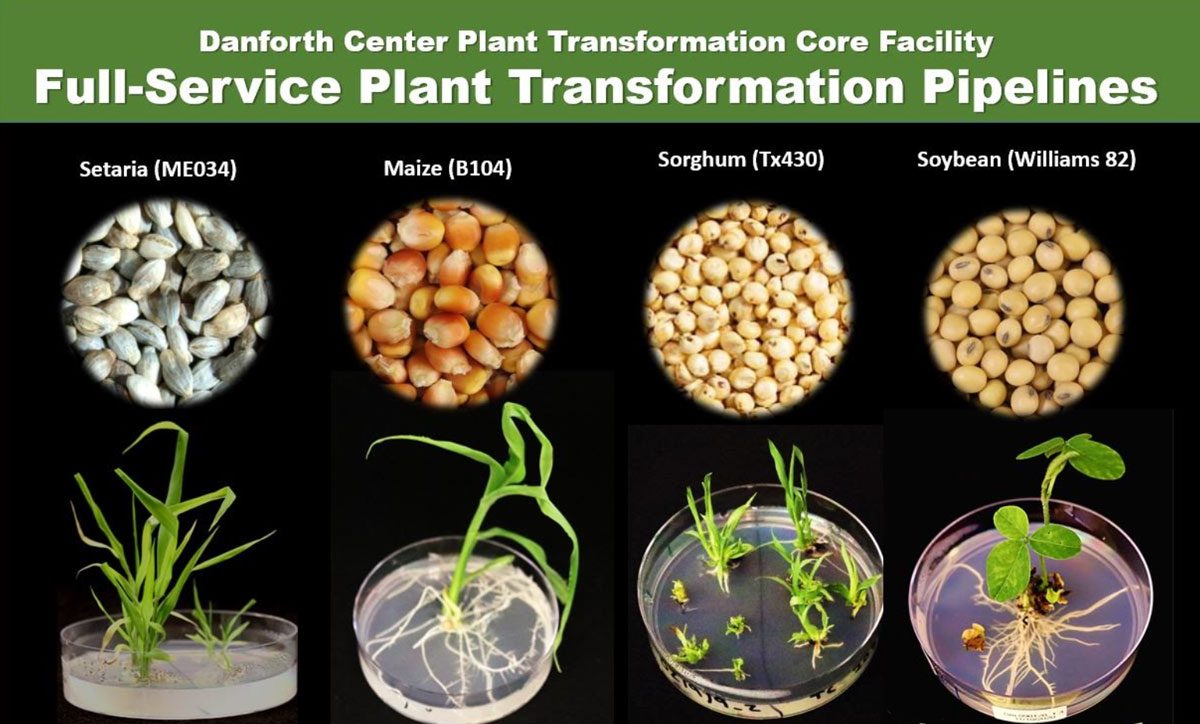

Under Veena’s leadership, the Plant Transformation Facility has grown to offer four transformation pipelines: soybean, corn, sorghum and setaria. The full-service transformation pipelines are a valuable resource for both Center scientists and burgeoning startups in the 39 North district and beyond.

Full-Service Transformation Pipelines, Plant Transformation Facility, Donald Danforth Plant Science Center

“I am proud to be able to create access for young startups to our plant transformation resources and expertise. It has been critical to accelerating the growth of many companies in 39 North,” explains Veena.

Kultevat, an innovator, processor, and brand of superior natural rubber based in Helix Center, is another 39 North company that is a regular user of the facility. Having access to the Plant Transformation facility at the Danforth Center has been instrumental in expanding Kultevat's R&D in biotechnology. “The level of assurance given because the facility is a dedicated space to this type of work is excellent,” says Jillian Silva, PhD, Principal Scientist at Kultevat. “Any questions that have come up have been answered promptly and any additional space that has been requested has been available immediately. Dr. Veena is beyond accessible to help with planning and give advice through her own expertise wherever she can. Kultevat looks forward to continuing work in the facility moving forward.”

Attracting companies to the ecosystem

In 2018, CTC Genomics, a newly formed subsidiary of CTC, the world’s largest sugarcane technology company, headquartered in Piracicaba, São Paulo, Brazil, selected BRDG Park for its North American research headquarters following a nationwide search. Key to their decision was access to some of the Danforth Center’s state-of-the-art facilities including the Plant Transformation Facility. “After visiting multiple sites, our encounter with St. Louis was the perfect environment to attract talent, and access unique infrastructures and transformation expertise for our bold start in the U.S.,” said Diego Henrique Souza Ferres, Head of R&D.

Maria Sorkin, Graduate Student in the Nusinow Lab, using equipment in the Plant Transformation Facility. In addition to offering full-service plant transformation pipelines, the Plant Transformation Facility offers self-service options, which gives companies in 39 North access to cutting-edge plant transformation equipment and infrastructure.

Collaborating With Danforth Center Labs

Veena and the Plant Transformation Facility also collaborate with Danforth Center scientists on a multitude of projects aimed at improving the human condition through plant science. Doug Allen, PhD, USDA Research Scientist, Member, and his lab have utilized the soybean transformation pipeline for multiple research projects. “The Plant Transformation facility is helping our lab make progress on projects quickly by advancing soybean lines through assay development,” explains Doug. “Veena is a go-to resource, knowledgeable, and I enjoy working with her.”

Dmitri Nusinow, PhD, Associate Member, and his lab also use the facility to generate transgenic plants for their projects. One of the biggest advantages for the Nusinow lab is the dependability of having an in-house plant transformation facility. “We were able to rely on the transformation pipeline even during the challenges of the pandemic over the last two years,” says Dmitri.

Research Experience for Undergraduate interns utilizing the Plant Transformation Facility equipment. Each year REU interns are trained on how to do plant transformations.

Plant transformation is a challenging technique, so the Slotkin lab brings the facility into the process at the very beginning, getting their input on how to set up certain experiments involving plant transformation. The communication line between the Plant Transformation facility and the Plant Growth facility has also been a huge help to the Slotkin lab. “When working with the Plant Transformation facility, they generate very valuable, rare plants,” says Keith Slotkin, PhD. “The Plant Growth Facility understands this and helps us take care of the plants. Both of the facilities go the extra mile to make sure we are set up for success.”

Veena wants the Plant Transformation Facility to continue evolving into the future. “We have plans to embrace new technology, and we want to be able to offer academic and industry clients access to the technology so we can continue to improve key crops.”